We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

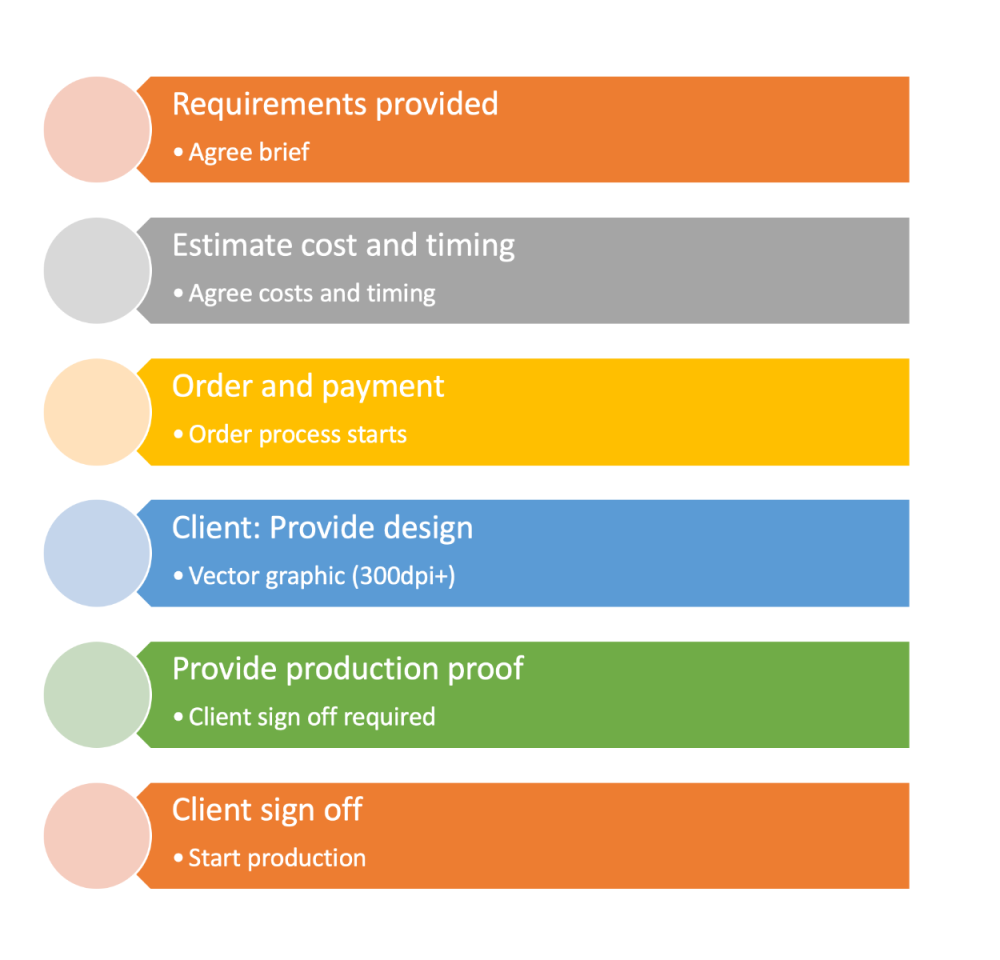

We create bespoke products with custom printed images at the highest quality. Typically our manufacturing process takes 10-12 days and few days to arrive in the UK, so we normally says 3 weeks from the order and the digital proof being signed off by the client. Depending on the material being printed on we can handle full colour quality printing and for harder plastics we can engrave and provide screen printing for more simple designs. We typically use offset printing for high quality results.

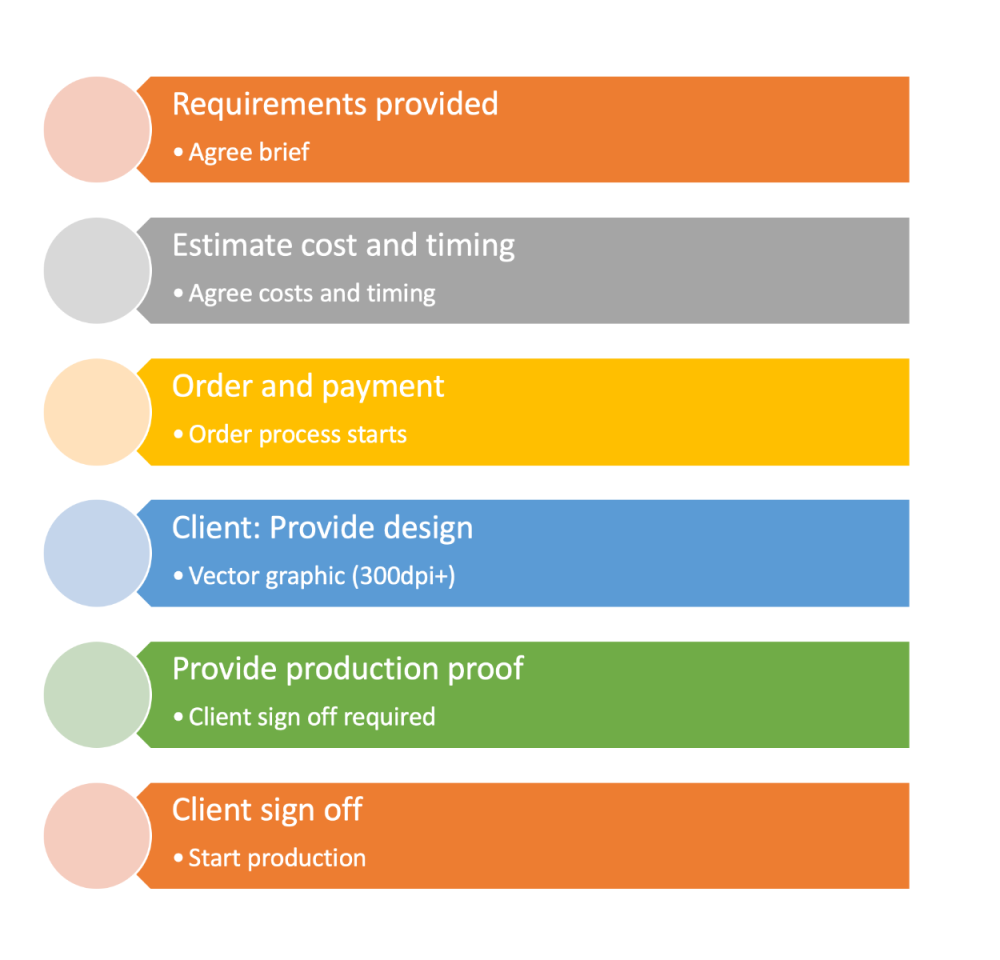

As all bespoke printing projects are different for each client we handle these via email and the phone so please contact us to explain your requirements HERE

As well as printing we can encode NFC stickers and products for you with static information or variable information held in a CSV file. When using CSV It is possible to have a column for the printed reference on the front of a sticker and a second column for the data to be encoded. Any encoding type is supported such as text or URI/URL and adding extensions such as an app to launch. If you required a spreadsheet of the chip UIDs that is also possible for everything we manufacture.

We are asked on occasions why we only print during the manufacturing process rather than locally on stock products like white PVC stickers. The answer is simple in that the standard of printing equipment in our factory is of a higher printing quality than anything available locally and once an item is NFC enabled the surface is no longer truly flat so getting the perfect finish is almost impossible. We print before the stickers and items are assembled so the finish is always perfect - so if you can wait it is always better to get produced at the time of manufacture.

When turn around time is short and a printed serial number or identifier on a sticker is required by the client we handle this by adding a removable label on the front or back for easy identification - so the product is not affected during the printing process.